General Detail

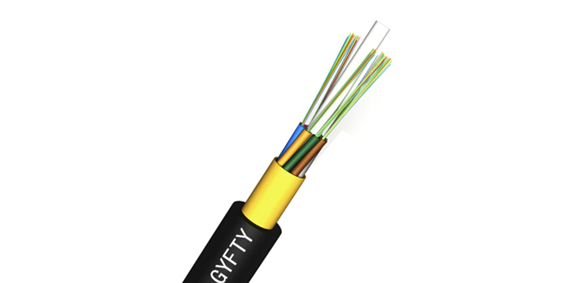

The 250 um fibers are positioned in loose tubes made of high modulus plastic. These tubes are filled with

water-blocking compounds. On top of the tubes, a water-resistant material is applied to keep the cable waterproof. Two parallel steel wires are placed

on both sides, and the cable is equipped with a polyethylene (PE) outer sheath.

- Product Features

- Product Specification

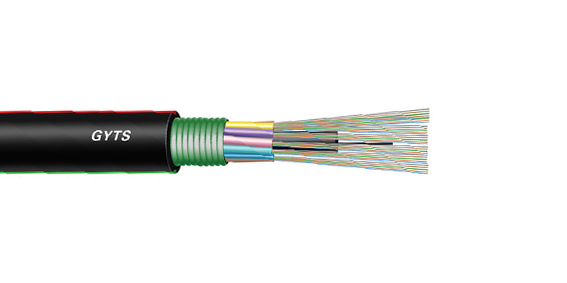

• Loose tubes contain a single jelly compound holding up to 24 fibers

• Water-blocking tape between the steel tape and loose tube with jelly compound.

• Double-sided corrugated PE steel tape with a steel coating.

• Dual parallel steel wires as strength members.

• Compact structure, lightweight, steel-coated tape with excellent water-blocking layer and good moisture resistance.

| Fiber Cores | 2~24 |

| OD(mm) | 8,0±0,3 |

| Tube | 1 |

| Normal Weight(kg/km) | 110 |

| Max Tensile Strength (N) | Short Term 1500 |

| Long Term 600 | |

| Max. Crush Resistance(N/100mm) | Short Term 1000 |

| Long Term 300 | |

| Min Bending Radius(mm) | Dynamic 20D |

| Static 10D |